Views: 33 Author: Site Editor Publish Time: 2025-12-03 Origin: Site

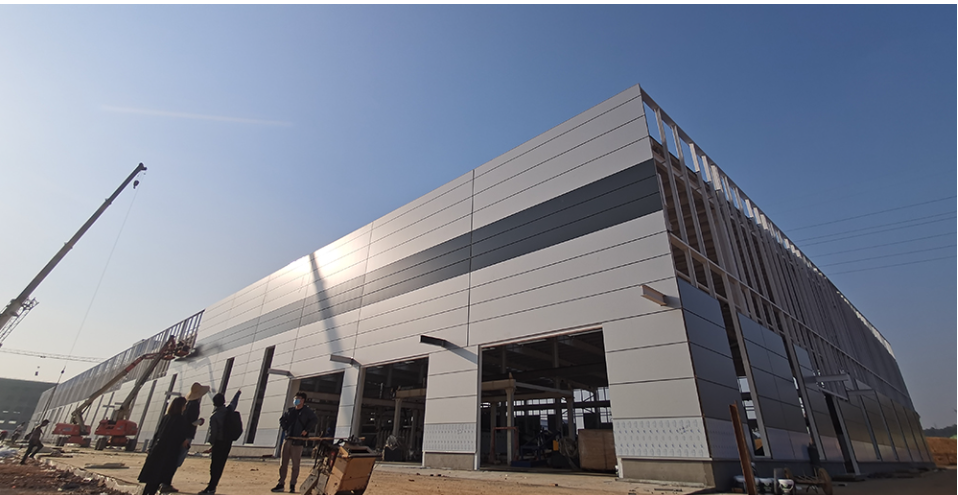

Project Name: Electronics Factory

Product Specification: 75mm Polyurethane Sealing Rock Wool Sandwich Panel

Modern electronic manufacturing facilities face increasing pressure to improve energy efficiency, enhance fire safety, and reduce operational costs. The new warehouse of a leading electronic factory required a warehouse exterior panel system that could withstand harsh environmental conditions while delivering stable thermal performance and long-term durability. Traditional building materials were unable to meet the project’s requirements for insulation, fire protection, moisture resistance, and fast installation.

High-Performance Solution: BRD 75mm Polyurethane Edge-Sealed Rock Wool Sandwich Panels

To address these challenges, BRD supplied its 75mm Polyurethane Edge Rock Wool Sandwich Panels, a proven system widely used in factory exterior walls, warehouse buildings, and modern industrial facilities.

This insulated sandwich panel system integrates thermal insulation, fire safety, waterproofing, and architectural aesthetics into a single high-performance envelope solution.

Three Technical Highlights of BRD’s Wall Panel Sandwich System

1. Rock Wool Core for Fire Safety & Thermal Stability

The 75mm rock wool core provides high R-value insulation, helping the warehouse significantly reduce energy loss and decrease HVAC operation costs.

At the same time, the A-class fire resistance of rock wool ensures the building meets stringent industrial safety standards—critical for electronic manufacturing environments.

2. Polyurethane Edge Sealing for Moisture & Weather Protection

BRD’s polyurethane edge-sealing technology creates a fully enclosed waterproof barrier, preventing moisture infiltration and corrosion.

This design enhances long-term durability, making the panels ideal for regions with heavy rainfall, temperature fluctuations, or strong humidity—extending the service life of the wall panel sandwich system.

3. Modular Design for Faster Installation & Improved Architectural Appearance

The lightweight, structurally strong insulated sandwich panels feature a precision interlocking joint system that minimizes thermal bridging and accelerates on-site installation.

Meanwhile, the clean and modern appearance of the rock wool sandwich panels gives the warehouse a visually striking, technologically modern façade—reinforcing the company's commitment to sustainability and innovation.

Project Benefits: Energy Savings, Superior Protection & Modern Aesthetics

With BRD’s advanced sandwich panel system, the new warehouse achieved:

Lower energy consumption

Higher thermal efficiency and R-values

Improved fire safety and moisture resistance

Enhanced building durability and stability

Modern, clean, and professional architectural appearance

Upon completion, the customer expressed full satisfaction with BRD’s product quality and installation efficiency. They have already confirmed their intention to collaborate with BRD again on future industrial construction projects.